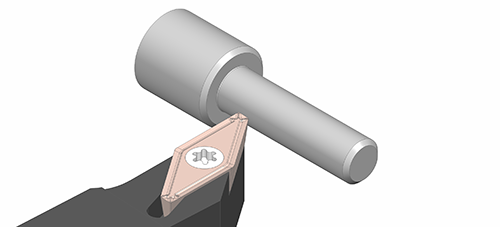

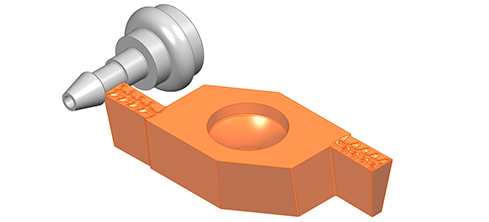

Success story 1

Insert VCGT 1103003 FR BI120

Controlled chip breakage for different cutting depths when machining an automotive part.

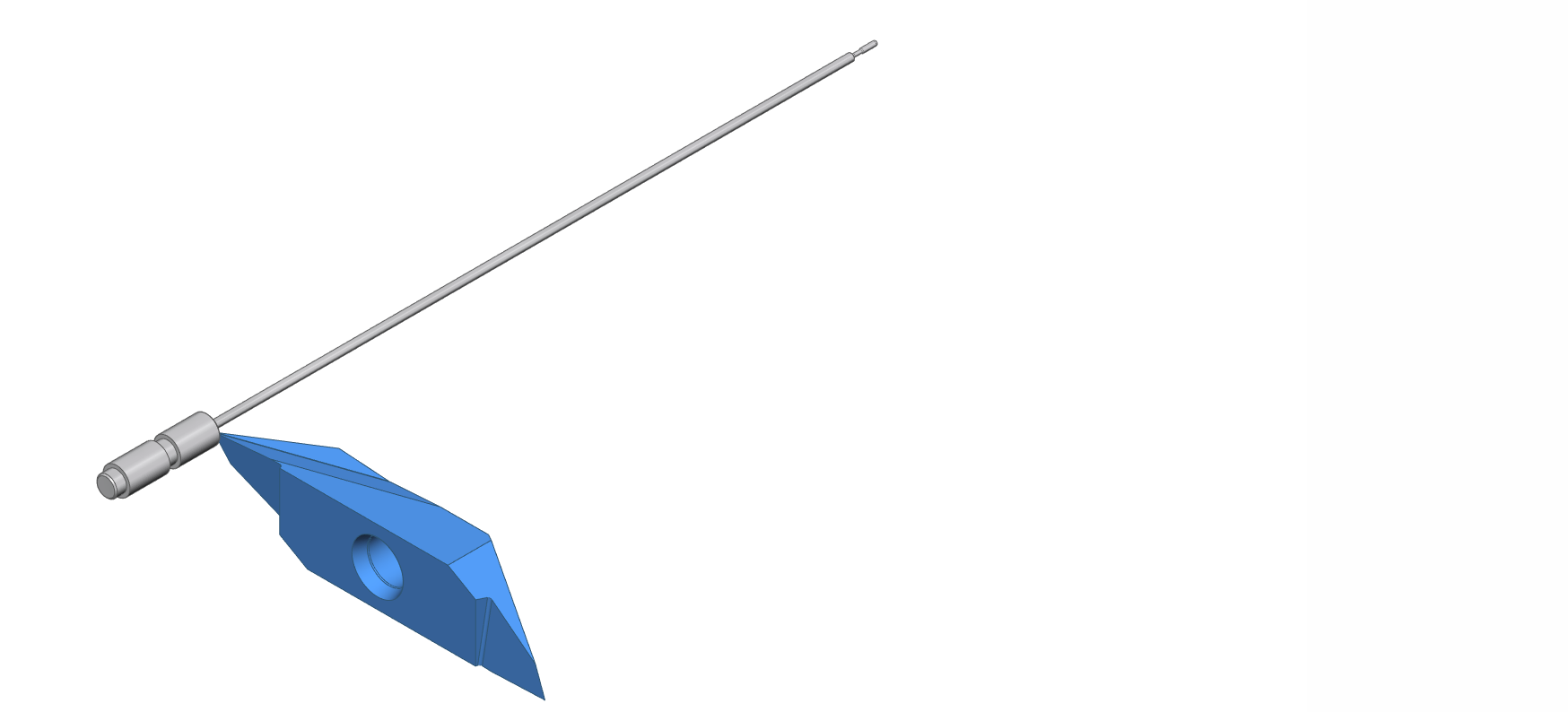

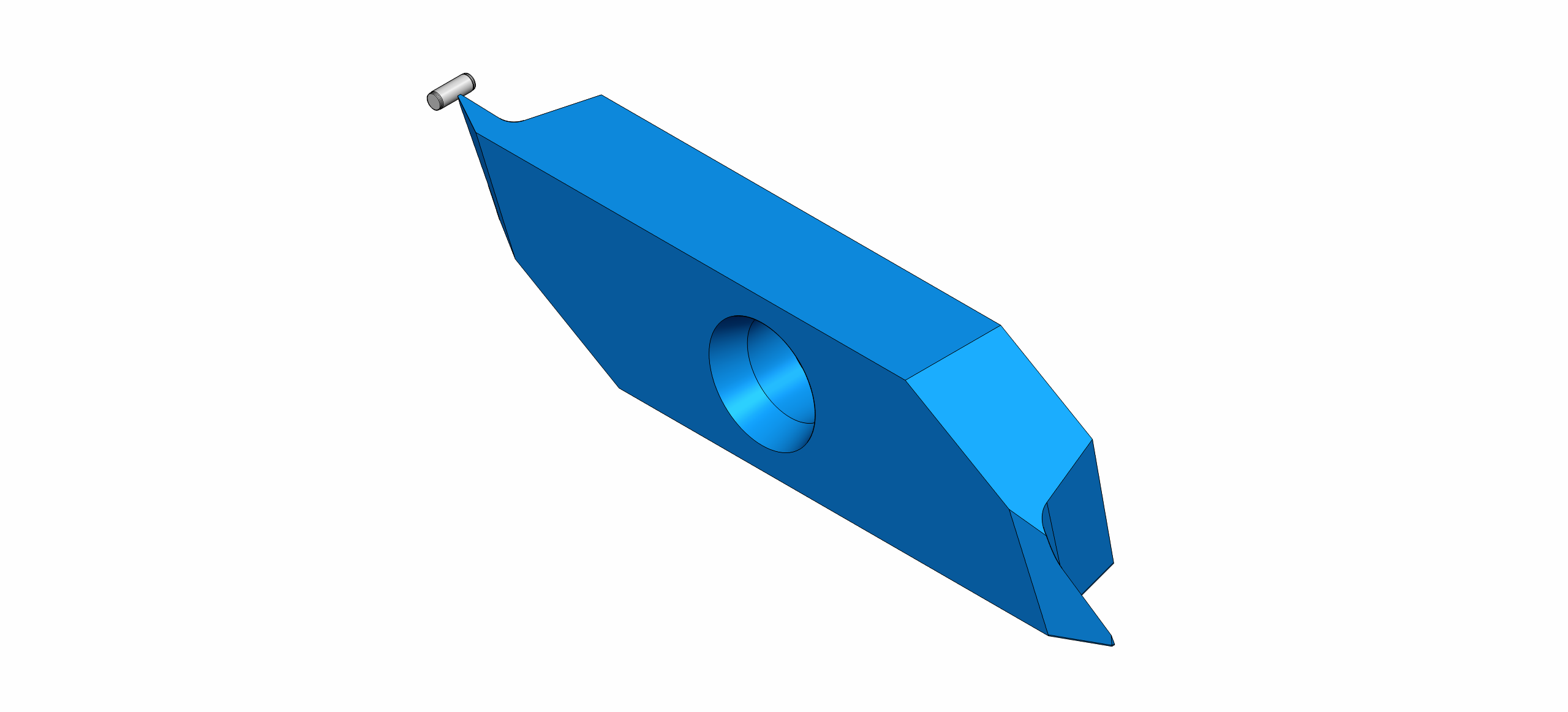

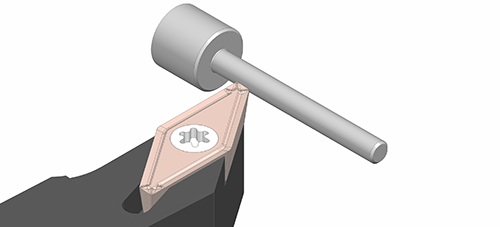

Success story 3

Insert 067R - 29° - r 0,04 - BI90

Machining a medical part with an unfavourable diameter/length ratio.

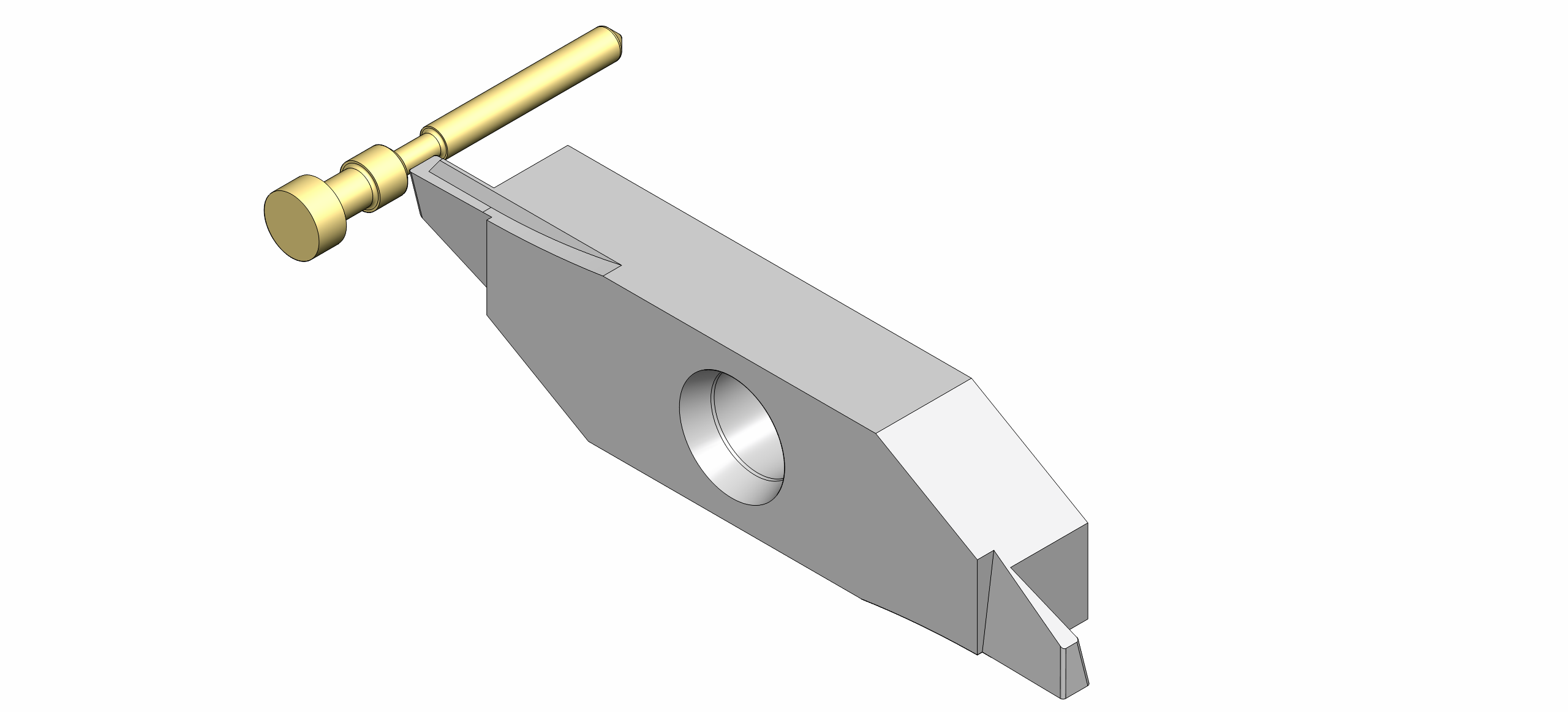

Success story 5

Insert 069R0,1 - 29° - 0,6 - BI80

Large-scale machining of a pin with high surface finish requirements.

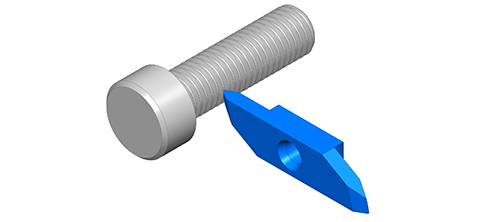

Success story 7

Insert 560RY1,5 - r0,15 - BI120

Increased tool life when machining a lead-free free-cutting steel part.

Success story 9

Insert 560RY1.5 - r0.05 - BI120

Improved chip breaking and evacuation during the machining of a titanium medtech part.

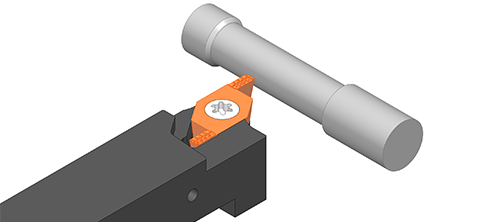

Success story 2

Insert VCGT 1103008 FR BI120

Substantial increase in tool life, allowing night-time production without intervention.

Success story 4

Insert TGP50N3,0 - r 0,2 - QM4

Significant increase in tool life when machining a watch part.

Success story 6

Insert 060RX1,0 - r 0,1 - BI110

Increased tool life when machining a lead-free brass connector part.

Success story 8

Insert 080R - 60° - BI100

Tool life doubled when machining a screw in Iconel 718.

Customer success stories 1-9

Customer success stories 1-9